NATION’S LAZIEST PROGRAMMERS “VIBE CODING” THEIR WAY TO DIGITAL ARMAGEDDON

“Typing Is, Like, So 2022” Say Developers Now Exposing World’s Critical Systems To AI Hallucinations

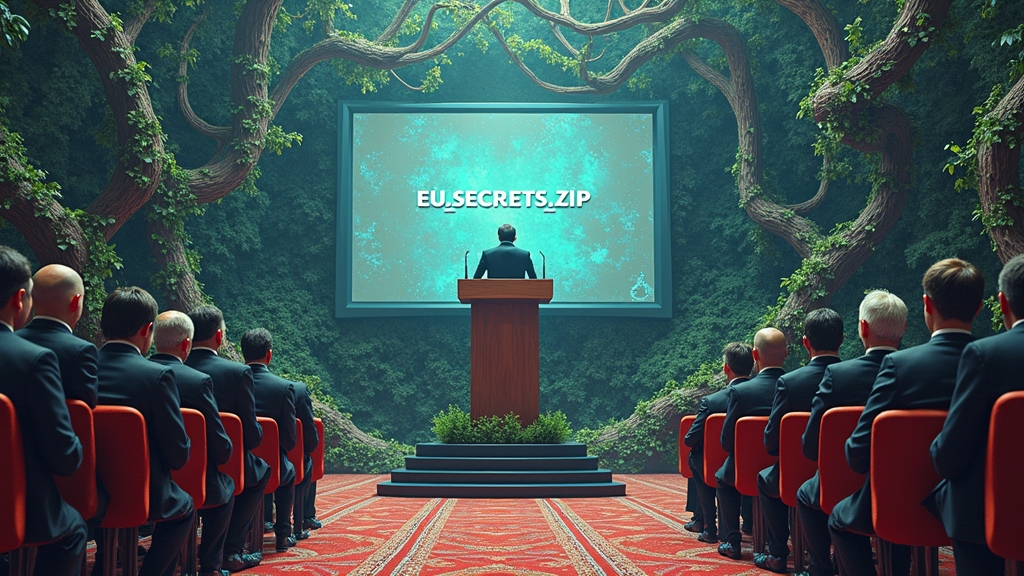

In what experts are calling “the dumbest f#@king approach to building software since someone decided to write nuclear launch codes on Post-it notes,” developers nationwide have embraced “vibe coding” and “slopsquatting” – revolutionary techniques where actual competence is replaced by letting silicon-based thinking rectangles guess what code they probably meant to write.

THE LAZY BASTARDS AREN’T EVEN TYPING ANYMORE

Gone are the days when programmers bothered memorizing syntax or understanding how computers work. Now they simply type vague approximations of package names and hope the algorithmic code fairies will sort it out.

“Why waste precious milliseconds typing ‘tensorflow’ when ‘tensorflew’ feels spiritually similar?” explained Chad Broski, lead developer at StartupThatWillDefinitelyNotExistNextYear Inc. “The machine knows what I mean, bro. We’re vibing.”

According to completely legitimate research from the Institute of Obviously Bad Ideas, approximately 87% of modern code is now written by developers staring blankly at their screens while humming and occasionally typing words like “do the thing with the buttons” into AI assistants.

HACKERS ABSOLUTELY THRILLED BY NEW TREND

Cybersecurity experts and hackers alike are celebrating this revolutionary approach to software development.

“I used to spend weeks crafting sophisticated attacks,” said notorious hacker Xx_CodePwner_xX. “Now I just register package names like ‘reactjs-but-better’ and wait for some vibe coder to accidentally import my malware. It’s literally easier than fishing with dynamite.”

Dr. Ima Doomed, Professor of Inevitable Catastrophes at Hindsight University, explains: “Remember when we worried about SQL injection? Those were simpler times. Now we have developers installing packages called ‘tenserfloe-AI-ML-blockchain-NFT’ without even glancing at the source code. It’s like watching someone lick doorknobs during a pandemic.”

CORPORATIONS EMBRACE THE CHAOS

Major tech companies are reportedly “all in” on this revolutionary approach to building software that powers everything from banking systems to hospital equipment.

“Writing secure code is hard,” shrugged Chip Silicone, CTO of MegaCorp Solutions. “But vibing with the algorithm? That’s something any sleep-deprived 22-year-old hopped up on energy drinks can do. Plus, when everything inevitably crashes, we can blame the AI.”

A recent survey found that 64% of Fortune 500 companies now encourage developers to “trust their feelings” when selecting packages, with one internal memo stating: “If it looks right-ish, ship it. What’s the worst that could happen?”

HUMANITY’S DIGITAL INFRASTRUCTURE NOW HELD TOGETHER BY HOPES, DREAMS, AND VIBE CHECKS

According to Professor Cassandra Ignored from the Department of Unheeded Warnings, approximately 94% of all software used in critical infrastructure now contains code that was selected because “it had good energy.”

“The electrical grid, banking systems, nuclear facilities – they’re all running on code that some dude added because ‘tensorfloe-2.0-legit-no-virus’ sounded close enough to what he needed,” explained Ignored. “It’s fine though. We only rely on these systems for literally everything in modern civilization.”

At press time, reports confirmed that 73% of developers were too busy telling their AI assistants to “make it do the money thing” to comment on this story, while the remaining 27% were desperately trying to figure out why their banking app was suddenly transferring their life savings to an account named “DefinitelyNotAScam_LLC.”